- Home

- Microfiber Fabric

- The microfiber we are manufacturing

- The microfiber manufacturing machines we have

Kingda was established in 2004, with a factory area of 5000 m² and more than 80 staff members. Kingda produces 10 million sports towels, eyeglasses cleaning cloths, and 1 million packing bags each month. Its annual output value is more than 70 million yuan.

Production Process

Multiple processes are needed to process raw silk into qualified microfiber. Besides strictly checking every process, Kingda also has strict requirements for choosing raw materials and manufacturing machines.

Raw Silk

Kingda only purchases AA grade raw silk from the listed company Shenghong Fiber to ensure quality at the source.

- Knitting

- Dyeing

- Setting

- Sanding

- Fabric Inspecting

- Imprinting

Logo - Inspection Packaging

- Shipping

Knitting

We use high-quality circular loom machines from German and Taiwan to weave gray cloth. The manufacturing machines have stable performance and low probability of wire breakage, which can ensure the woven gray cloth has a flat surface without joints.

Dyeing

High-quality dyes produced by Transfar Group offer high color fastness and contains no azo, ensuring the materials passes the EU REACH test.

Setting

The fabric dyed by high temperature dyeing cylinder must go through high temperature setting, to ensure the stable width, gram and flat surface.

Sanding

According to the production process, Kingda has customized a sanding machine, with a fine sanding effect and no lint shedding.

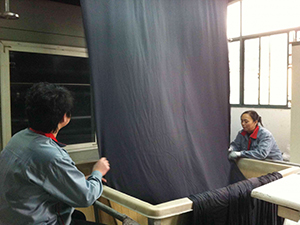

Fabric Inspecting

All fabrics will be tested before leaving the factory, including for cloth defects, width, gram and color difference, and the detail information of the fabric will be recorded.

Imprinting Logo

Imprint a variety of logos according to customer requirements.

Inspection Packaging of Finished Product

Full inspect and random inspect of all finished products, ensure the product quality.

Shipping

Export package, stacked by list, keep dry and clean.

The earliest textile fibers used by people were natural fibers - cotton, hemp, wool, silk, among which, silk is one of the best wearing fibers and its linear density is about 1.0dtex. The originally developed chemical fibers could only reach a linear density of 5-6dtex and failed to provide the wearable comfort or beautiful appearance of silk.

Read More- Good Cleaning Effect

- Strong Water-absorbing

- Quick drying

- Soft and Comfortable

- Easy Cleaning

- Long Service Life

In order to confirm the quality of microfiber products, Kingda only purchases AA grade raw silk from the listed company Shenghong Fiber to ensure the finished products’ quality after dyeing and finishing at the source.

We always use the quality raw materials, and are equipped with complete equipment sets such as circular loom machine, dyeing machine, stenter machine and textile finishing machine to achieve the quality standards.

Read MoreKingda was established in 2004, with a factory area of 5000 m² and more than 80 staffs nowadays. Kingda produces 10 million sports towels, eyeglasses cleaning cloth and other products, and 1 million packing bags.